Supplier Spotlight: How Uniscan is walking a step ahead

Can you tell us about your story with Uniscan?

“Aside from the occasional family discussion over the years as the business evolved and lending a hand in the factory from time to time in the early days, I had no prior experience of the mobility industry.

“Originally, I came from an engineering background but gravitated to sales and marketing. I joined Uniscan in 1999 after leaving my role as Senior Account Director within an international marketing organisation.

“Uniscan had reached a point in its development where dedicated marketing was required and my credentials and experience fitted the brief. As a family business it was a natural fit for me to work alongside my father and brother.”

What have been the biggest changes to the firm as it has evolved?

“There has been greater investment in tooling to improve manufacturing lead times. Adapting to and embracing electronic technology was a big change, and this included creating a website and introducing barcoding. Another was bringing the powder coat spraying process in-house.”

How do you think shopping habits have evolved for walkers over the years?

“Consumers now have greater access to information enabling them to understand their needs and how to fulfil them. There is a far greater choice of products available today both through mobility retailers and online. This combination of choice and knowledge presents a serious challenge to manufacturers and suppliers and highlights the crucial requirement to stand out from the crowd.”

What have been the proudest moments for you at Uniscan?

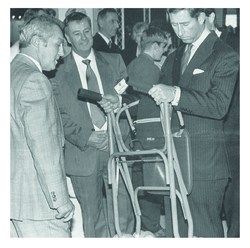

“The proudest moment for me when was my dad (Tom Morris) set the company up. He had been made redundant from a senior engineer post and during his redundancy helped my Nan and one of her friends by making them walkers in his garden shed using copper tube. The rest as they say is history!

“There are some other highlights for me which occurred after joining Uniscan – one is identifying the need for a three-leg walker with an integral rest seat and successfully bringing it to market – these are our Triumph models, which took years to develop and finesse.

“I am also particularly proud of the fact that we are a British manufacturer and have established a solid reputation for quality and service. Despite incredible competition, we have survived and are thriving.

“In recent years I have invested lots of time, effort and money in our production facility to improve our lead times. We currently achieve 7-10 working days (and in a lot of instances much quicker), which we think for a bespoke handmade product is pretty good. Bearing in mind that we only make walking frames it may come as some surprise that we manufacture almost 1,000 variables!”

Uniscan has focused solely on manufacturing walking frames. Was it a conscious decision not to branch out into supplying other mobility products?

“Our expertise and experience is walking frames and we have worked hard to establish ourselves as specialists in this field. There is a lot more to walking frames than people realise, and we recognised very early on that branching out to supply other mobility products would potentially dilute our USP and our specialised ability to provide quality made-to-measure products.”

Which product do you regard as a bestseller at Uniscan?

“The Triumph three-leg walker with an integral rest seat is currently our best seller. This product is a classic example of market/consumer collaboration. After extensive research we identified a requirement for a three-leg walker with a seat and in response we designed, developed and then launched the Triumph range in 2001.

“It now comes in three models with a choice of eight colours – the Triumph Plus model (our most recent addition to the range) has extra stabilising legs and comes in two seat heights. As with all Uniscan walkers the product is supplied fully assembled ensuring that retail staff or the end user do not have to put it together.”

A Uniscan walker is typically solid aluminium. What do you see as the advantages of this metal?

“All Uniscan walkers are manufactured from aircraft grade aluminium tube which meets British Standards quality. We chose this material due to its relative strength to weight ratio. Aluminium tube is lightweight and malleable (meaning we can make the bends in the tube easier in production). It’s also good for the environment at its completely recyclable.

“All Uniscan walkers are mechanically fastened as opposed to being welded – this allows us to repair any damage or wear and tear that may occur rather than replacing the whole walker. There are many other materials used in the production of walkers, all of which have their pros and cons.

“However, the materials we use along with production methods we employ are tried and tested. We know that a Uniscan walker can last well over 15 years as people often utilise our refurbishment service. In fact we have customers who have had one of our walkers passed on to them that we can trace back to our very early beginnings – this is happening more and more.”

What is the average customer looking for in a walker?

“There is no average customer when it comes to walkers (at least not for Uniscan). We are all different in terms of height, size, shape, and what colour we like, which is why we strive to provide a unique, bespoke solution for each customer.

“The variables mentioned previously mean that we can genuinely offer the customer an individual product to suit them including choices of: model, seat height, frame width, braking system, frame colour and accessories.

“As we make to order no retailer has to stock every item to have access to it – retailers don’t need to place a minimum order, and they can be safe in the knowledge that we can provide the right product solution for their customer.”

Can you tell us more about your latest products to hit the market?

“The Grand Glider Plus Adjustable, which is our four-leg bariatric model, is available in four seat heights, eight frame colour choices plus a range of accessories. This model is manufactured to take a maximum user weight of up to 40 stone (254kg) but is also lightweight and features a built-in rest seat.

“Another recent addition to our product line up is the 23” (584mm) seat height platform Triumph Plus walker providing a delta design solution for our taller clients. Both these products have been warmly embraced and sales activity is excellent.”

What do you think makes a Uniscan walker stand out in the market?

“Uniscan walkers are unique in many ways. A British designed and manufactured product with an amazing track record in terms a quality, stability, and range. A walker from Uniscan is lightweight, amazingly strong, constructed from quality materials and specifically designed for indoor and outdoor use.

“When closed for storage it folds, locks together and stands unsupported taking up minimal floor space. We are also very fortunate to have a friendly, knowledgeable office team available to answer questions and provide help when needed.”

How are your products distributed in the UK?

“Our products are distributed primarily through the mobility retail network here in the UK. We are very fortunate to have such a great, passionate, and dedicated group of retailers selling our products and it’s a privilege to have such a good relationship with them.

“Quite a few retailers will remember my father Tom and his infectious laugh! We also sell directly to the public, through large buying groups and into the NHS and social services.”

Are you looking to expand your dealer network?

“We are always happy to consider enquiries from interested mobility retailers to open a trade account with us. We offer POS, product training, after sales support and product advice.

“Whilst we sell directly to the public we guarantee not to sell below our MRRP as we very much value and respect our retail partners. Details of all retailers that sell Uniscan products are listed on our website and signpost people to those who stock our walkers.”

“Uniscan work with individual retailers on a one-to-one basis to support any offers or promotions they may be running. To try and support our retailers through these challenging times we have taken the huge decision to hold our current prices despite the current economic conditions.”

How has Uniscan Walkers managed to navigate challenges in the past year, such as global supply issues?

“The challenges in past few years have been testing – not just for Uniscan but for everyone in the mobility sector. As we have been in business for very close to 40 years it means that we have built up a very strong, close network of regular suppliers.

“When there were supply issues, we have been able to work with our network to find alternative solutions to maintain our production process.”

What’s next for Uniscan Walkers over the next 12 months?

“The next 12 months will be interesting for all businesses, and at Uniscan this will be no different. After almost 40 years in the industry we have weathered highs and lows, seen companies come and go and worked our way through some tough economic periods.

“Whilst this experience provides a solid platform, we have to make our way through the current economic situation but we will also be keeping an eye on where we can develop, grow and move forward as a business.

“We are constantly looking at ways we can streamline production whilst still hand-building. This ensures that we can check the quality of the build at each stage of the process – along with any additional benefits we can add to the Uniscan range of walkers.

“From the first version of the Uniscan walker back in May 1983 to present day we have never stopped listening to feedback or exploring ways to improve our brilliant product.”